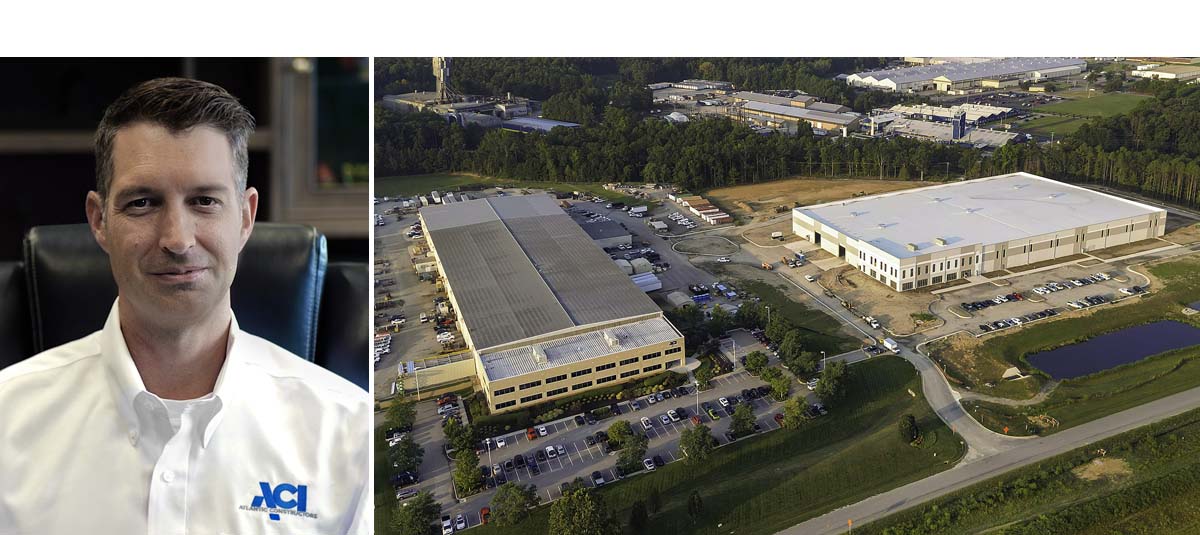

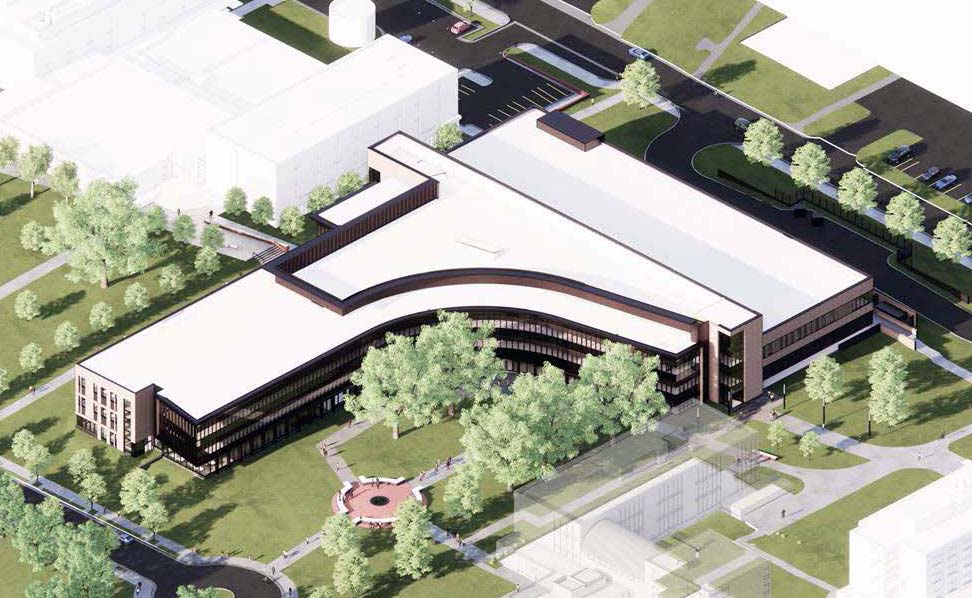

Looking over at ACI’s HQ2 facility, it’s looking a lot like a finished structure. Do we have a hard date on when it will be “open for business?”

Yep. We’re still right on track for opening that facility the first week of November. It’s getting close, and amazingly, we’ve been tracking towards that date for two years now and haven’t moved it. The construction’s progressed really well. It’s kind of amazing how well you can stick to a schedule when you’re self-performing most of it yourself, right?

Absolutely! Once it’s complete, we know a lot of the Atlantic Modular work will be going on over there, but what other activity can we expect over at HQ2?

So really, there’s three main things to think about relating to the new building. The first is that we’ve grown a lot, and we just flat out need more office space. There wasn’t room to really add office space here at HQ1 without taking away from current fabrication space; so that was one objective— create more office space. Looking at staff to move, the easiest choice was a group that doesn’t really need direct proximity to everyone else, which is our Service group. They can operate pretty much standalone, so that’s why they’re getting a brand-new office space in the new facility. That will enable them to continue their growth trajectory, and once they move out of their current space, that will allow our other services to grow into that available space that they vacate.

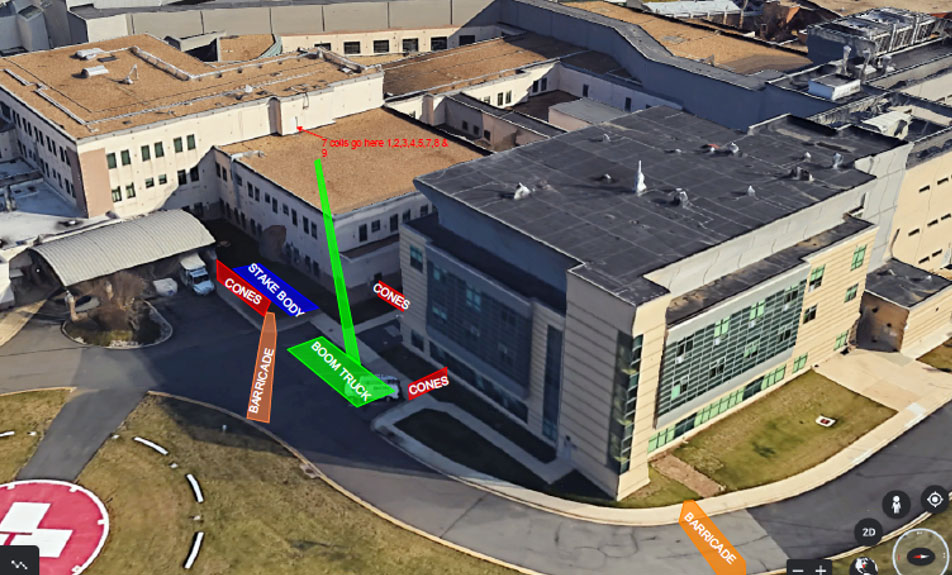

The next thing to consider is that we have a few things that happen in other facilities, located about 20 miles away, closer to downtown Richmond; we lease some space there just for logistics and things like that. When trucks show up to deliver things that can’t go to the job sites yet, those things currently have to sit in storage there until they can go to the job sites. Now, that can be brought here and kept next door.

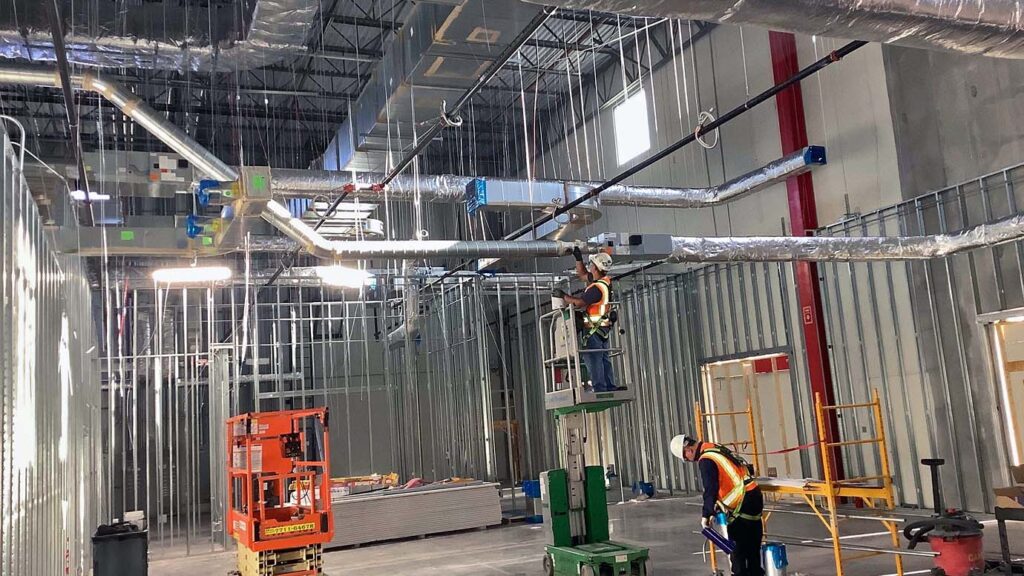

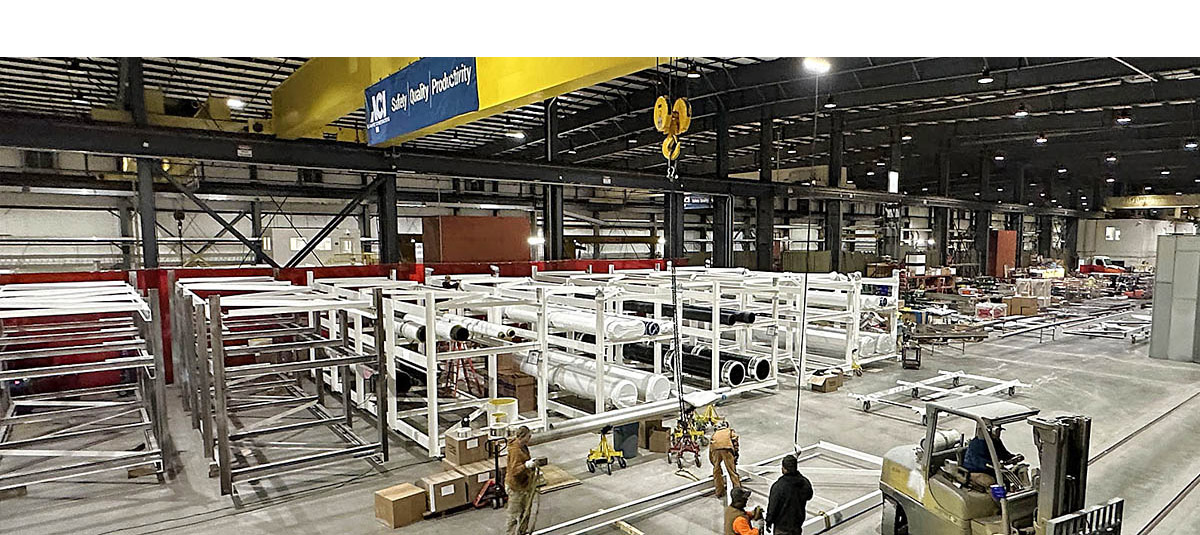

Having everything take place sort of on one campus adds tremendous efficiencies. But the most significant additional service, modular construction, takes up a lot of space. That is a major growth area for us, and we expect it to grow considerably more in the very near future. So, at least a third of the building will be dedicated solely to Atlantic Modular. This will put us in the 250,000 square foot range solely for fabrication and assembly.

ACI has long had a tremendous differentiator in our massive fabrication shop, which a lot of competitors don’t have. Now that we we’re essentially doubling the square footage, is there anybody in the region that has that kind of space?

There are other contractors across the country – they’re very few– that have some significant space in the same realm of what we do, but we don’t know of any others who have the space paired with all the capabilities we possess at ACI. What we’re doing now is bringing two core competencies together, two competitive advantages, which are size and scale plus diversity of services. Once you combine the two of those, we really feel like we are offering something unique to the industry.

ACI has been doing very solid modular work throughout the region, streamlining and improving their processes for years. How is Atlantic Modular different?

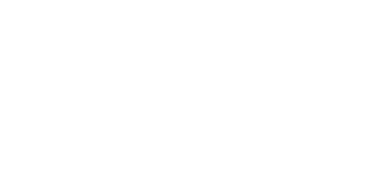

We’ve been doing modular fabrication for a long while. It became a big focus about 10 years ago when we started making very large multi-trade assemblies here instead of on-site. And that’s what led to us doing our first shop expansion about six years ago, to have room for that modular in addition to our other shops. We knew that Modular was where the industry was headed. And we knew that’s where we were going, but it wasn’t until the last three years that we really realized how big this could get. And that’s when we started pursuing modular as a product line itself, and not necessarily just servicing our own projects, but as a service out to direct customers.

What would be an example— a line of business or a type of customer— that perhaps ACI couldn’t pursue but will be able to now?

The biggest advantage to modular is that it opens up our customer base geographically. Right now, it’s very difficult to pursue projects outside of a couple hours from your main office; you don’t have field crews or supervision and things like that that can extend that far.

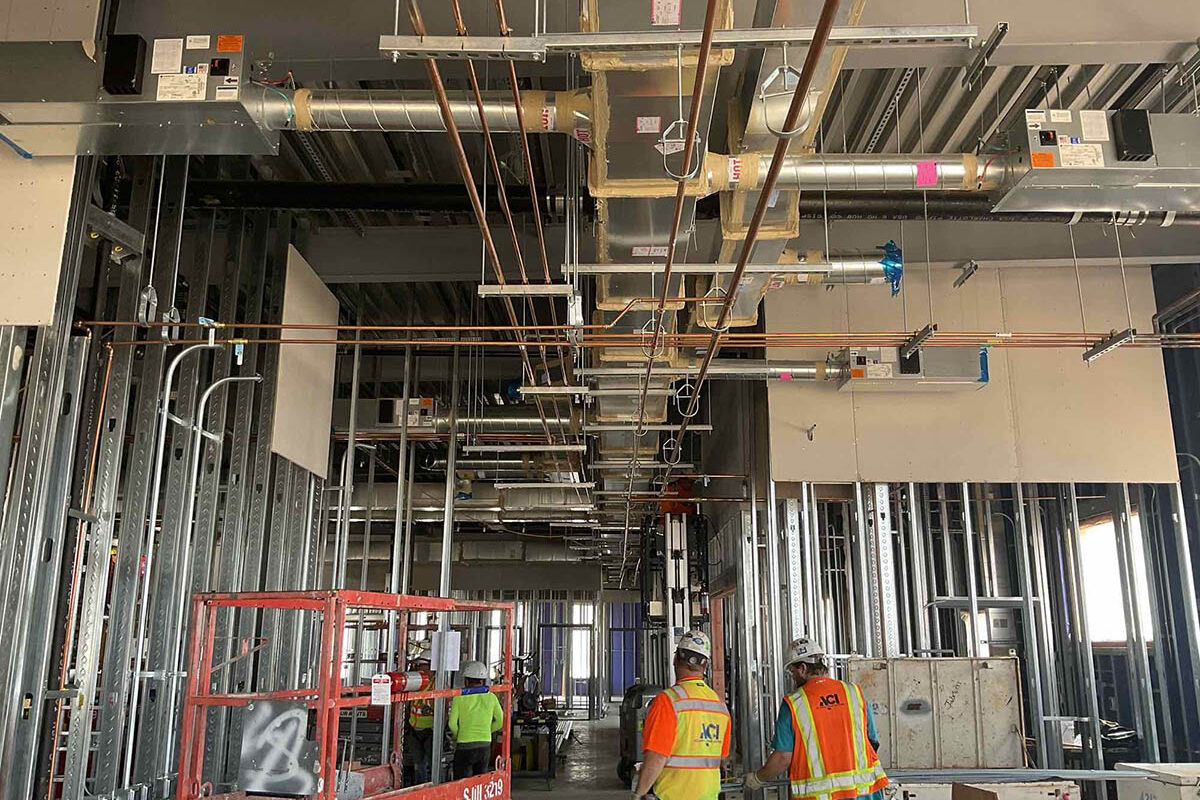

But with modular, since 90 plus percent of the work happens right here, under our own control, we just put it on a truck and we can send it just about anywhere, including globally. And we are now starting to look at those international projects, as well as the advantages that come with being able to target some of the more cyclical work in different areas of the country. Historically we’ve been pretty much tied to the market in the Virginia and North Carolina areas. Now, if there’s a project anywhere in the U.S., we can pursue it.

Is there anything else you would want people to know about our capabilities, particularly with modular and the new facility? Are these changes bringing something to bear that may not be top of mind for customers?

Sure. Two things that seem like they differentiate us specifically within the world of modular against the others that are doing this is our capacity. We can produce a high volume of work very quickly. And a lot of clients need things very quickly, and also need them at a very high rate. We now have the capacity to complete and ship multiple orders per day to help meet the needs of those customers.

The other piece of this is that we’re extremely vertically integrated: we self-perform everything that has to do with these skids. While most other companies may be good at a single aspect, they either have to hire other companies to come in and do the other parts or they may just kind of “try to get it done” perhaps not particularly well. But for us, we absolutely have a core competency and have been doing for decades things like, steel coatings, blasted paint, mechanical piping, plumbing, HVAC, sheet metal, electrical, and fire protection. Essentially, every service it takes to put one of these modules together, we can self-perform right here. That’s how ACI is able to feed that capacity, by having complete control over the quality and quantity of those services.

With all that in place, what do the next five years look like for ACI?

Actually, this is growing so fast that it’s difficult to project where it’ll be five years from now, but we do think that within the next two years we’re going to be able to produce five times as much modular construction as we are now. Our biggest limiting factor has been space and that’s about to be solved.

So, HQ2 solves the space challenge, but what does the manpower situation look like? We often hear about the how difficult it can be to find people.

That’s a great question. Modular is significantly more efficient than traditional construction in the field; you can do significantly more modular with the same number of people that you do traditional construction. So even if we just have to slightly cut back on the amount of traditional construction we do, we can redirect that same workforce into modular and still produce significantly more. But to your question, we are even now bringing on additional people to support modular construction.

With all of this expansion and the ability to reach even international customers, it seems like ACI is on an extraordinary trajectory. Is there anything else you’d like people to know about the company?

The biggest takeaway is just that Atlantic Constructors is the greatest company on the planet and there’s absolutely no reason not to reach out to us. We’d be glad to help all our customers reach their goals of creating the buildings that support their missions.