ACInsider Year in Review 2024

The past year was a very good one for ACI, with continued growth both in personnel and capabilities throughout Virginia and North Carolina. While we completed a number of very successful large-scale projects and were awarded several others, there is one project in particular that is not only near to our hearts, but crucial to ACI’s growth and ability to take on projects anywhere in the world: the completion of our 170,000 sq ft sister facility, dubbed “HQ-2.” With this new building, we have effectively quintupled our fabrication ability and cemented ourselves as a provider of reach and scale in the world of modular construction.

ACI is clearly a company focusing on the future, but even the most forward-thinking organizations need to pause periodically to look back. Below, we invite you to do just that.

Atlantic Constructors HQ-2

170,000 MORE Square Footage

About this Project

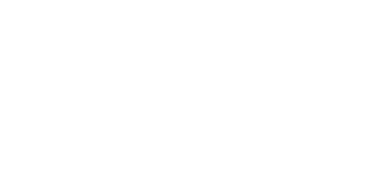

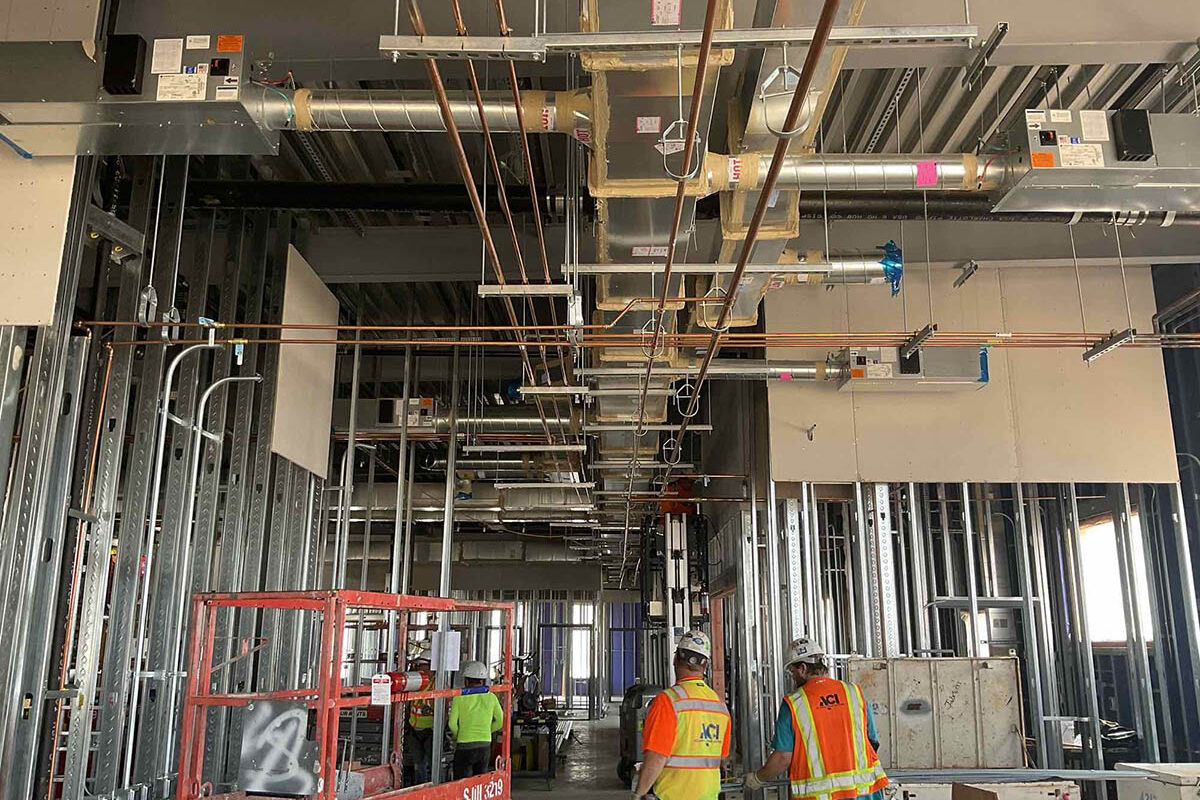

ACI was the tenant upfit general contractor and self-performed Mechanical, Electrical, Plumbing, Fire Protection, and Fire Alarm on the new ACI HQ2- Office and Distribution Center consisting of warehouse space, first floor offices, and second floor mezzanine. The new office space houses the Service and Special Project Groups while the warehouse area consists of the new tool room, shipping and receiving, and the newly formed Atlantic Modular division.

With this build, ACI doubles-down on their long-term commitment to be on the leading edge of modular construction with approximately half of the new building dedicated to modular construction. This equates to about 250,000 square feet solely for modular fabrication and assembly, which gives ACI the capacity to produce five times as much modular construction – all under one roof.

In addition to more modular construction, the new space allows for ACI’s Service Division to increase their efficiency and continue to offer the unparalleled service for which they are known.

– 2 RTUs

– 3 ARUs

– ESFR Sprinkler heads to allow for further expansion of warehouse operations

– Full Uponor plumbing system

Medical Imaging and Emergency Room

New Construction of Dual Use Medical Facility

About this Project

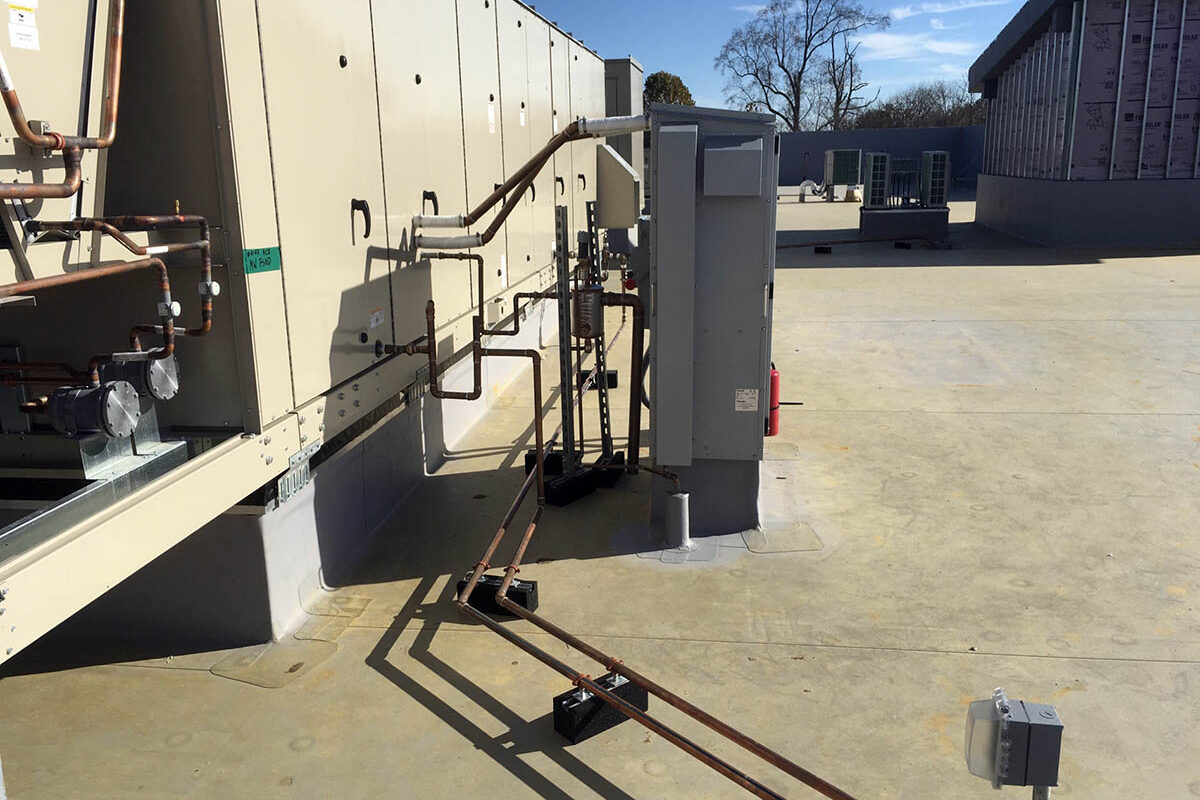

Mary Washington Harrison Crossing is an ACR-accredited facility staffed by qualified, caring imaging teams and physicians dedicated to the comfort of patients and in-house Board-Certified, Fellowship-Trained Radiologists. ACI was awarded the mechanical and plumbing scope of work through preconstruction efforts working the W.M. Jordan. Virtual Design Construction was utilized early due to an accelerated schedule and coordinating workable above-ceiling space with dense utility systems. Ductwork and piping were fabricated for just-in-time delivery due to the limited lay-down area on site.

– 2 RTUs

– Two packaged RTUs

– One energy recovery unit

– 40 VAVs

– Six split systems

– 250 GRDs

– Installation of owner provided chiller

– 40,000 lbs of sheet metal

– 80 plumbing fixtures

St Francis Medical Center Hospital

175,440 s.q ft. Expansion of Existing Hospital

About this Project

ACI was tasked to upfit the Fire protection in the existing MOB building and install new systems for the vertical expansion of the existing hospital. This portion of the hospital had two existing levels, with levels 3 & 4 consisting of new construction along with two new mechanical penthouses on level 5. The new vertical expansion was supplied by a new wet pipe standpipe system. There was also extensive renovation work done in the hospital existing MOB, which included almost the entire floors of levels 1 and 4 MOB, as well as some 3rd floor MOB work. The hospital remained operational throughout the renovation process.

Confidential Owner

A Decade-long Relationship Continues

About this Project

ACI was engaged in the first of four data center projects in Boydton, VA, over a decade ago, resulting in project success and relationships that have grown our project resume to be one of the leading mission-critical contractors in Virginia today. ACI completed over $30M in mission-critical construction services in 2023 alone, which creates a combined total of $76M for this series of projects.

– Completion of one 250,000 Data Center Facility while starting another 250,000 SF data center facility

– 160 Air Handling units per facility

– 160 Supply Louvers, damper assemblies (ACI Prefabricated)

– 160 Return Lovers, damper assemblies (ACI Prefabricated)

– 2 Air Handling units, and associated HVAC equipment dedicated to admin office spaces

INOVA Health System

Loudon and Fair Oaks Hospitals

About these Projects

ACI Sterling continues to build momentum and forge strong relationships, as illustrated by continued partnerships with Inova Health Systems. Most recently, ACI was selected to assist with the two following major projects at two of Inova’s facilities— Fair Oaks and Loudon Hospitals.

Inova Fair Oaks Hospital

AHU 4 Replacement

Inova Fair Oaks Hospital needed to replace a failing AHU (AHU 4) that had been in service since 1985. This unit served critical spaces, including Operating Rooms #5 through #8, and supplemented the adjacent Sterile Core. ACI’s scope of work was to install the new AHU4 unit alongside the older, failing AHU-4, which would remain in operation during the install, start-up, and commissioning of the new unit. The project required modifications to the piping, duct work, roofing and storm drainage systems associated with the existing AHU 4 and new AHU 4. Modifications to the Existing Electrical Feeds, BAS Controls, and Fire Alarm Systems were also required.

– New AHU 4 designed for 16,000 CFMs w/ Steam Pre-Heat, Humidification, Chilled Water Cooling and 2nd Stage Cooling via DX Coil and Separate Condensing Unit.

– New 8’ x 53’ Roof Curb Install to support the new AHU 4.

– 1,800 Sq Ft of TPO roofing system replacement.

Inova Loudon Hospital

Hospital Steam Bypass

The INOVA Loudoun Hospital Campus had a Steam Boiler Plant serving the original hospital and a newer Steam Boiler Plant serving the New Tower. They wanted the ability to have either Steam Boiler Plant serve both buildings from either plant in the event of repairs needed.

ACI’s role was to interconnect both building’s steam and condensate systems via bypass piping, isolation valves, flash arrestors, and an additional condensate return pump skid. This called for the provision and installation of piping supports between both buildings along the existing roofing systems and attachments to structural steel below the roofing system with water proofing patches at each location.

– 1,000 feet of 6’’ Steam, 4’’ Condensate and 2.5’’ Pumped Condensate Piping.

– 120 Gallon SS condensate receiver skid with duplex pumps rated for 45 GPM discharge at 50 psi.

– Coordination and execution of steam outages and cross connection between two 24/7 hospital campus buildings averaging 300 occupied beds per day/night.

Goodwill Melrose Plaza

Renovation of 101,000 SF Facility

About this Project

ACI performed the HVAC, plumbing and electrical on 101,000 sq ft existing Goodwill facility. The renovated building will include new classrooms, wellness center and a grocery store. The grocery store was a critical part of the project as in required a special RAC unit for refrigeration. With a deadline of November 1st, ACI had the grocery store finished ahead of schedule. Project is tracking to finish on time and in budget by May 2025.

–21 RTUs

-New Switchgear

-65,000 lbs of ductwork

-All new fixtures

VCU Health Main Hospital

3rd Floor IR Renovation

About this Project

The VCU Health IR Main 3 project included 43,000 square feet of renovation scope on the 3rd Floor of the Main Hospital at Virginia Commonwealth University Medical Center to support the needs of VCU Health System Authority.

The significant renovations to accommodate five new interventional radiology rooms, two new CT rooms, two new procedural ultrasound rooms, a new fluoroscopy room, a new twenty‐five bay prep‐recovery area, new radiology reading rooms and clinical and administrative support space. The scope of the project also includes the construction of a new 7,500 SF mezzanine between the 2nd and 3rd levels to accommodate administrative offices and support space.

– AHU replacement of an existing air handling unit currently on the 4th floor of the Main Hospital

– Temporary AHU staged and tied to existing duct to provide conditioning in the hospital while the unit was being replaced

– The project was completed in multiple phases due to coordinating scope with active healthcare services

Lego Warehouse

Upfitting a Massive 270,000 SF Facility

**UPDATE**

In addition to the Lego project detailed below, ACI has been awarded select mechanical, electrical, and plumbing trades on Lego Group’s 1.7 million sq ft precision production facility just south of Richmond in Chesterfield, Virginia. Over the next few years, we’ll be hiring 1,761 people in a range of professional and production positions. The people who join our team will have a unique opportunity to grow with our organization.

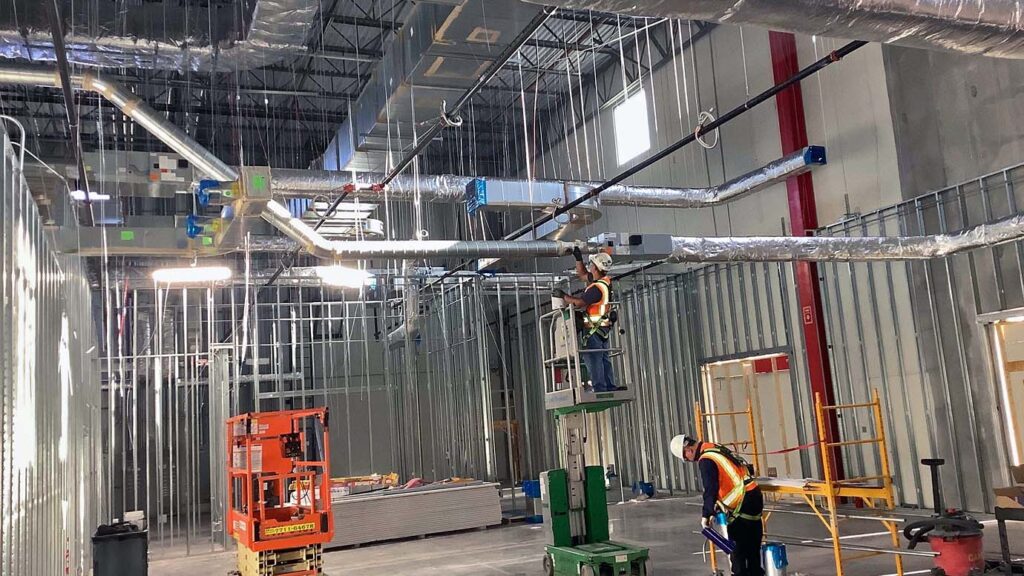

About this Project

ACI was awarded the Mechanical, Electrical, Plumbing, and Fire Protection scopes for an upfit to an existing 257,000 SF warehouse. This facility serves as a temporary training location for new hires of the permanent Lego facility soon to be constructed nearby. We were aware from the beginning that the schedule for this project was accelerated and ACI was prepared to successfully meet the challenge of that timeline.

The warehouse work included new HVAC units, an additional electrical switchboard, lighting, copious amounts of duct work and plumbing fixtures, low voltage work and sprinkler pipes.

– One 6 Ton Air Cooled Chiller

– 20 Package Roof Top Units

– A total of 291 GRDs were installed in the office space.

– ACI installed over 8,800 feet of pipe (copper and cast iron)

– 2000-amp switch board added existing 3000-amp main electrical service

– 2 Package DX Air Handling Units

– 79 plumbing fixtures installed in the building, including the emergency eyewash and wall hydrants in the warehouse space

– 30 VAVs

– 2 Air Compressors and accessories for complete system directed by Lego

– 16 forklift battery chargers were installed

NOVA Semiconductor Site

Confidential Semiconductor Site in Manassas VA

About these Projects

At this facility, the APVC Diluted Acid Waste Piping had reached “End of Life” due to exposure to direct sunlight at torn insulation areas and heat trace voltage inconsistencies to be replaced. ACI was tasked with replacement of the PVC Diluted Acid Waste Piping and Pump Headers with TIG welded Stainless-Steel piping.

- Six total pump replacements over four phases of work and over a one-year project duration.

- 12’’ Suction Headers and 10’’ Discharge Headers

- All Piping Spools were Passivated to remove any trace carbon content from the interior surfaces at a North Carolina Vendor Location.

Industrial Sustainability and Environmental Compliance Project

Confidential Owner and Confidential Pharmaceutical Manufacturing Client

About these Projects

As Prime Mechanical, ACI was trusted by the owner to drive the project schedule, other specialty trades, and ultimately, ensure the project success.

ACI’s Self-Performed Scope of Work on this $30M Sustainability and Environmental Compliance project consisted of:

- Process Equipment Removal and Replacement – Heavy Rigging and Equipment setting using Hydraulic Truck Cranes to 30 T

- Piping Systems Included PVC & CS SCH40 & SCH80, SS 304L & 316L SCH40 & SCH 80, Alloy 20 Swagelock & Alloy 400 Tubing

- Extensive Support Steel fabrication and installation included Pipe Racks, Pipe Bridges, Structural Pipe Supports Systems, Etc.

- Fabrication and Installation of various operational, reliability and maintenance access enhancements – Ladders, Platforms, Cross-Over Stairs, Etc. with self-performed shop applied Epoxy Paint Systems and Trade Partner Galvanizing.

- Architectural Enhancements to PEMB’s – Elevated Concrete Mezzanines, Flatwork on Grade and Equipment Pads

- Various Trade Partner/Subcontractors performing Concrete, Insulation, Crane Lifting, Scaffold and Coatings.

- There was elevated and confined space entry work in an operating area of an industrial manufacturing facility

Project Schedule:

- 8 months Shop and Field fabrication of steel piping

- 14 months of Field installation of steel piping

- Various coordinated 24/7 outages

Dominion Energy HVL

Fire Protection for Office and Laboratory

About this Project

ACI provided Fire Protection on this 84,000 sq ft project, a new four-story office building, as well as a High Voltage testing lab. ACI FP installed a new fire pump to supply the office building with a wet pipe standpipe system, as well as a deluge system for the testing lab to supply the water powered oscillating monitor nozzles.

Confidential Data Center

Specialized Fire Protection

About this Project

ACI’s Fire Protection Division wrapped up two Data Center projects this year, making a total of four over the past three years for the same customer. The total square footage of all four projects combined is a whopping 2,479,551 for contract amounts totaling $15M

The scope of work performed in these two most recent Data Center projects consisted of 27 Sprinkler Systems, 25 Pre-Action and 2 wet systems.

– Pre-Action Sprinkler systems utilize Nitrogen Generators to fill sprinkler pipe with inert gas to significantly extending the longevity of the sprinkler system.

– Over 120,000 feet, or 22.5 miles of sprinkler pipe.

– Worked with DPR to pre-fabricate a Multi-Trade Rack which housed sprinkler bulk feeds.

# # #

Atlantic Constructors, Inc. is a full service industrial and commercial contractor headquartered in Richmond, VA with satellite offices in Newport News, Roanoke, Hampton Roads, Sterling, and Wilmington, NC. Our highly skilled team of over 1100 employees serves customers across the country and around the world. For more information, visit www.acibuilds.com.