FABRICATION

We hold the following certificates of authorization from the American Society of Mechanical Engineers (ASME):

– Fabrication and assembly of pressure piping

– Manufacturer of pressure vessels

We hold the following certificates of authorization from the National Board of Boiler & Pressure Vessel Inspectors:

– Metallic Repairs and/or alternations

– Registration of boilers and pressure vessels manufactured in accordance with stamps “PP” and “U”

Areas of Fabrication

Our sheet metal shop can fabricate ductwork up to a 10 gauge thickness, paneled duct work, dust collection systems, material-handling chutes, and any specialized industrial sheet metal. Our coil line and plasma cutters are fully automated and networked with our computer aided drafting (CAD) services to provide quality as well as expedited services.

Our sheet metal shop can fabricate ductwork up to a 10 gauge thickness, paneled duct work, dust collection systems, material-handling chutes, and any specialized industrial sheet metal. Our coil line and plasma cutters are fully automated and networked with our computer aided drafting (CAD) services to provide quality as well as expedited services.

Piping is welded and systems pre-fabricated using automated welding machines, orbital welders, and other modern tools. Our ASME “PP” & “U” and NBIC “R” and “U” code certified fabrication shop works with all alloys and pipe sizes from ½” through 60.” Whether it is orbital welding, TIG, MIG, SMAW, or soldering, we can do it. All of Atlantic Constructors’ welders are ASME certified.

Piping is welded and systems pre-fabricated using automated welding machines, orbital welders, and other modern tools. Our ASME “PP” & “U” and NBIC “R” and “U” code certified fabrication shop works with all alloys and pipe sizes from ½” through 60.” Whether it is orbital welding, TIG, MIG, SMAW, or soldering, we can do it. All of Atlantic Constructors’ welders are ASME certified.

Structural Steel and miscellaneous metals of various alloys are cut, drilled, welded, blasted and painted all right here in our high-tech facility. You can count on us to create expertly cut, welded and finished systems that install flawlessly and operate smoothly.

Structural Steel and miscellaneous metals of various alloys are cut, drilled, welded, blasted and painted all right here in our high-tech facility. You can count on us to create expertly cut, welded and finished systems that install flawlessly and operate smoothly.

We have the ability to apply any specified finish to your piping, steel, and equipment in our in-house blasting and painting booths.

We have the ability to apply any specified finish to your piping, steel, and equipment in our in-house blasting and painting booths.

- Each booth is 70’L x 17’W x 14’H

- Totally enclosed, controlled atmosphere

- VOC/hazardous waste compliant

- Fed via rail, forklift, and (2) 15-ton cranes

- Documented adherence to SSPC /NACE recommended practices

- Ability to apply sophisticated, multi-coat finishes

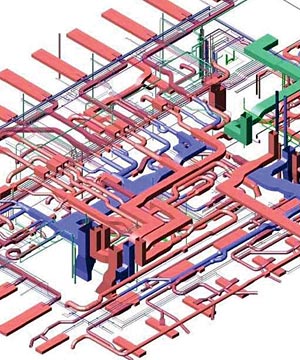

Computer Aided Drafting and Computer Aided Manufacturing are an integral part of our fabrication process. With fifteen CAD stations, we are able to coordinate and create detailed drawings for our steel, ductwork, piping, plumbing, and fire-protection systems. We can meet the needs of your project, whether through Building Information Modeling (BIM) or simply 3-D coordination. Our CAD files are downloaded directly to our fabrication equipment. This equipment includes:

Computer Aided Drafting and Computer Aided Manufacturing are an integral part of our fabrication process. With fifteen CAD stations, we are able to coordinate and create detailed drawings for our steel, ductwork, piping, plumbing, and fire-protection systems. We can meet the needs of your project, whether through Building Information Modeling (BIM) or simply 3-D coordination. Our CAD files are downloaded directly to our fabrication equipment. This equipment includes:

- Ductwork coil line

- Plasma cutters

- Steel Beam/Drill Line

- Roto-Weld automated pipe welder

- Watts Pipe Cutter

This download process, and the associated fabrication equipment, reduce the possibility of human error and insure a quality product for our customers.