ACInsider Fall 2023

Table of Contents

The Future of Construction Is Modular...

...and ACI Has Been Doing It For Years

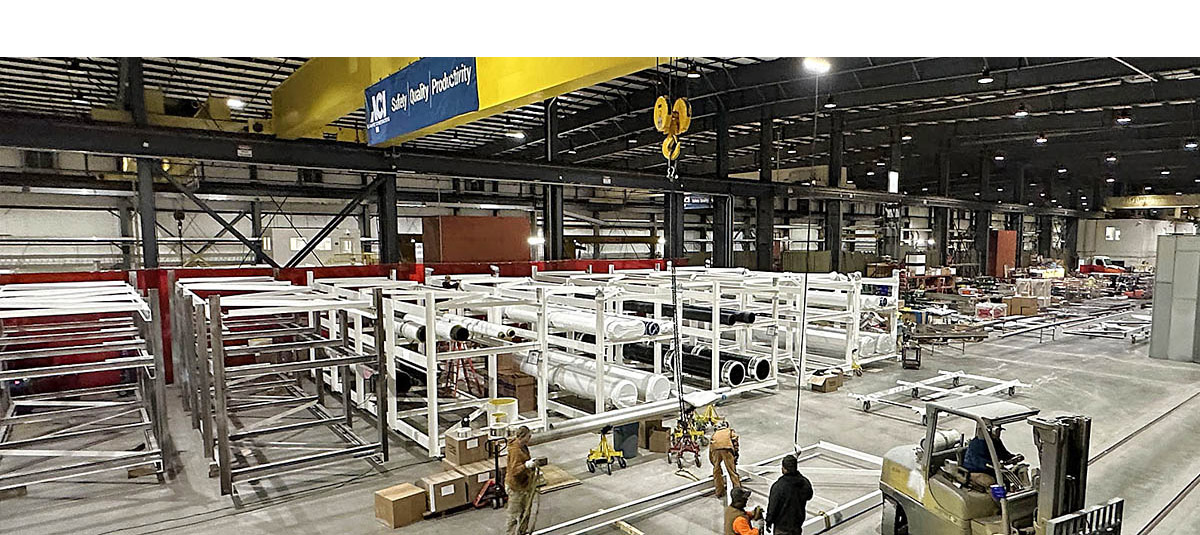

Modular construction. It seems the phrase is everywhere these days, with pundits and industry watchers everywhere touting modular as the future. And they’re right, of course, but at ACI we’ve been working on this particular wave of the future for years, perfecting our standardized approach to design, build, and deliver large-scale, complex modular components that provide the best experience and finished product for our customers.

Without a doubt, modular construction is transforming industrial construction, bringing with it unprecedented advantages that allow us to uncouple from a project’s timeline; designing, creating, and precommissioning full MEP systems in our off-site, controlled environment for later integration.

The key to our ability to accelerate timelines lies within our massive, fully automated 170,000 square-foot facility. We leverage self-performed design and fabrication all under one roof for maximum, turn-key efficiency. Our extensive capabilities range from structural steel, sheet metal, process piping, plumbing, and electrical, to virtual design, fire protection, and blast and paint. With our own experienced riggers and fleet of vehicles, we not only design and manufacture fully integrated solutions, we transport and install them as well.

Atlantic Modular’s approach offers the flexibility to quickly adapt to complex industrial applications, ensuring seamless integration of advanced systems and evolving technologies. Our modular techniques streamline processes and increase sustainability, unlocking a range of powerful advantages for our customers:

Accelerated Project Timelines: Modular construction allows for parallel workflows, where site preparation and off-site fabrication occur simultaneously. This significantly reduces construction times compared to traditional methods, enabling faster project completion and the start or resumption of operations sooner.

Cost Efficiency: With Atlantic Modular, economies of scale factor heavily. By fabricating components at our controlled environment, material waste is minimized, and costs are optimized. Additionally, these streamlined processes and shorter construction schedules contribute to overall cost savings for you.

Enhanced Quality Control: Off-site modular construction ensures a superior level of quality control. Atlantic Modular conducts rigorous QA inspections and utilizes standardized processes for consistently high-quality results.

Flexibility and Adaptability: Industrial facilities often require complex configurations and the integration of advanced systems. Atlantic Modular provides the flexibility to meet these requirements with precision and speed. Components can be customized, allowing for seamless integration of specialized equipment, machinery, and technologies, ensuring your project is tailored to your unique needs.

Reduced On-site Disruption: One of the key advantages of modular construction is the reduction in on-site disruption, as much of the construction takes place in our off-site fabrication facility, minimizing work stoppages and delays at your facility.

Increased Safety: With more work being done off-site, the danger on-site accidents is greatly decreased, both for ACI and our customers.

When you choose Atlantic Modular, you get our decades of experience and expertise and our commitment to surpass your expectations with extraordinary results. Contact us today to learn more about how our innovative modular solutions can transform your industrial project into a streamlined, cost-effective reality.

The Importance of Apprenticeships at ACI

Signing Day 2023

Newly signed apprentices at ACI’s Apprenticeship Signing Day

Apprenticeship programs play a vital role in construction, serving as a cornerstone for skills development, workforce training, and career advancement. These programs offer a specialized learning experience that combines hands-on training with classroom instruction, equipping participants with the practical skills and theoretical knowledge necessary to excel in their careers.

A study conducted by the National Skills Coalition found that nearly 80% of construction firms reported difficulties in finding qualified workers. Apprenticeships not only provide targeted training that aligns with the industry’s needs and reduces skill shortages, but also offer participants a pathway to long-term career stability. The Construction Industry Institute points out that skilled craft professionals who undergo formal apprenticeship training are more likely to have extended careers, reduced turnover rates, and increased job satisfaction.

At ACI, we are committed to providing the best opportunities for our employees. To do so, we are working vigorously to increase our participation with apprenticeship programs offered by Associated Builders and Contractors (ABC) and the Roanoke Technical School. These programs encompass several trades — Electrical, Plumbing, HVAC, Sheet Metal and Fire Protection and require three years to complete.

Apprenticeship programs must be accessible and affordable to be successful. At ACI, anyone can sign up and first year tuition is paid by ACI and reimbursed by the employee. If the employee maintains a “C” average, graduates, and either gets their journeyman license or completes an additional year of employment, ACI will reimburse the tuition costs. In Richmond, both day and evening classes are available; Tidewater and Roanoke currently offer evening classes.

To promote these programs, ACI holds high-visibility events such as our annual Apprenticeship Signing Day, complete with fun photo-ops and prizes. We encourage our hiring managers to offer the program to employees during the hiring process as well as throughout the year. We regularly send out notices about upcoming sign-up events via our internal communications platform and we maintain interest through updates and posts about Graduation and major milestones of our participants. We encourage our apprentices to share their experiences with their peers to highlight the benefits of participation.

Apprenticeship programs facilitate the transfer of knowledge and expertise from experienced professionals to the next generation of workers, ensuring our industry remains adaptable and innovative. We want to help our employees increase their skills and knowledge and we want to increase the number of people in the trades as older generations transition out of the work force. As we help our employees build more successful careers, we also foster a culture of continuous learning and increased skills. This benefits our workforce and adds even more value for ACI’s customers.

Empowering Our Employees

ACI's Employment Engagement Platform

The Power of Communication

It’s Business 101 that customer communication plays a pivotal role in the success of any company. At ACI we continually strive to keep the channels of communication with our customers wide open and accessible. If we don’t, neither of us will be successful.

But what about internal communications? We believe that all our employees represent ACI, and for that to be true, we all must be aligned and connected to our company culture and values. That’s no easy task, with more than 1,000 employees and multiple locations. Fortunately, technological innovations have provided us with an innovative method to easily interact and share information.

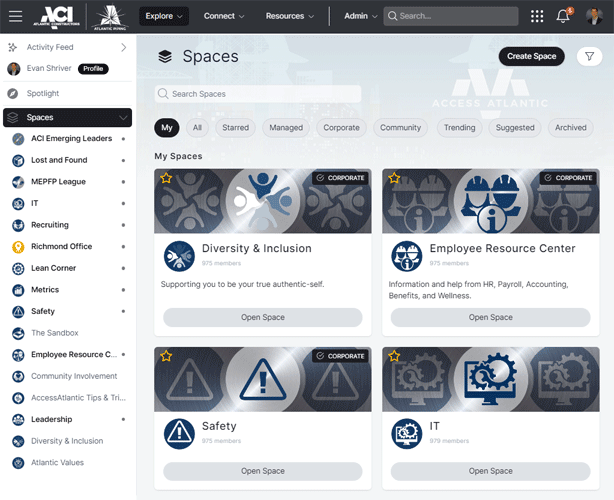

SPACES allows for group communication and collaboration.

Meet AccessAtlantic

One such innovation at ACI has been the implementation of WorkVivo (internally branded as AccessAtlantic), our Employee Engagement Platform. Accessible to everyone within the company, AccessAtlantic is a digital environment where employees interact, share feedback, exchange ideas, and easily find. In addition to being an important work tool, it has become a key contributor to organizational success, engaging employees to align them with ACI’s core values and amplifying our company culture.

According to ACI President Terrence Kerner, “AccessAtlantic brings all the great things that are happening across our large organization and presents them right in front of us so that we can all feel better connected to each other and our mutual accomplishments. It links our goals and values to the content which our teammates share… from jobsites to fabrication to personal interests and accomplishments. Simply put, AccessAtlantic allows us to celebrate, share, and learn in a way that would be physically impractical otherwise.”

We believe that true employee engagement is crucial to ACI’s ability to deliver on the promise of our mission, vision, and values. Here are just a few of the ways our digital engagement platform is helping us ensure that we continue to provide unmatched service and solutions:

Empowering Our Employees: A social-media-style communications platform provides an inclusive space where employees’ voices are heard and ideas are shared. This empowers individuals at every level, leading to higher job satisfaction and increased loyalty.

Enhancing Inclusion and Retention: AccessAtlantic enables employees from diverse backgrounds and departments to connect and collaborate, breaking down silos and promoting cross-functional collaboration. By leveraging our collective intelligence, we can develop innovative solutions for customers while retaining top talent.

Boosting Productivity and Efficiency: AccessAtlantic offers real-time updates, instant messaging, and notification features that eliminate communication bottlenecks and reduce the time spent on back-and-forth emails or phone calls.

AccessAtlantic is bringing these and a host of other advantages to ACI. By providing real-time information, fostering inclusivity, enabling employees’ voices to be heard, and promoting cross-functional collaboration, we are creating an environment that best reflects the values of our company. For our customers, this means enhanced customer service, more innovative solutions, and an exceptional customer experience with extraordinary results.

ACI Expands to Accommodate Growth

New Facility to Neighbor Existing HQ

What do you do when your 170,000 square foot facility helped propel your company to such a level of success that you now require even more space? Well, if you’re ACI, the answer could not be more obvious.

As you can see, the wooded lot beside our headquarters is undergoing a massive change. It’s all in preparation for a major new construction project: ACI’s second 170,000 square foot facility. Turns out, when you consistently provide extraordinary solutions for your customers, you gain more customers—who want more extraordinary solutions!

Set to come online in October of ’24, the new facility will play a huge role in ACI’s future direction. Evan Shriver, ACI’s CEO, says, “We know that Modular Fabrication is the future of construction. Not only does it increase safety, quality and efficiency of our own projects, it allows us to pursue projects all across the country, without having to move our employees. ACI is already building MEP and Fire Protection systems here to be shipped and installed onsite by other contractors, and we are getting orders for more. It’s a much safer, much more efficient model, but it requires a lot of space. And that space will also help us with our growth in other areas so we can continue to provide all our customers with extraordinary solutions.”

Highlights of the New Facility:

DGS Central Lab

New Lab Construction

About this Project

Scheduled for completion in 2026, ACI will be performing the mechanical, plumbing, and fire protection scope on this new 300K SF lab facility located in Mechanicsville, Virginia. ACI combined scope for this Skanska project is more than 40M.

The building will function as laboratory space, training space, and office space for two independent agencies. This project will increase efficiency by allowing regional DFS operations to be housed in a single facility while also providing space for future expansion.

ACI will be performing the mechanical, plumbing, and fire protection scope on the new 300,000 square foot lab facility.

– 2,000 tons of centrifugal chiller cooling

– Heat shift screw chiller

– Custom AHU’s

– 350 VAVs

– 4-Pipe FCUs

– Tracking air valves

– 35 VRF units

– 3 Cooling Towers

– 6 Boilers

– 620,000 tons of sheet metal

VSU New Academic Building

Alfred W. Harris Academic Commons

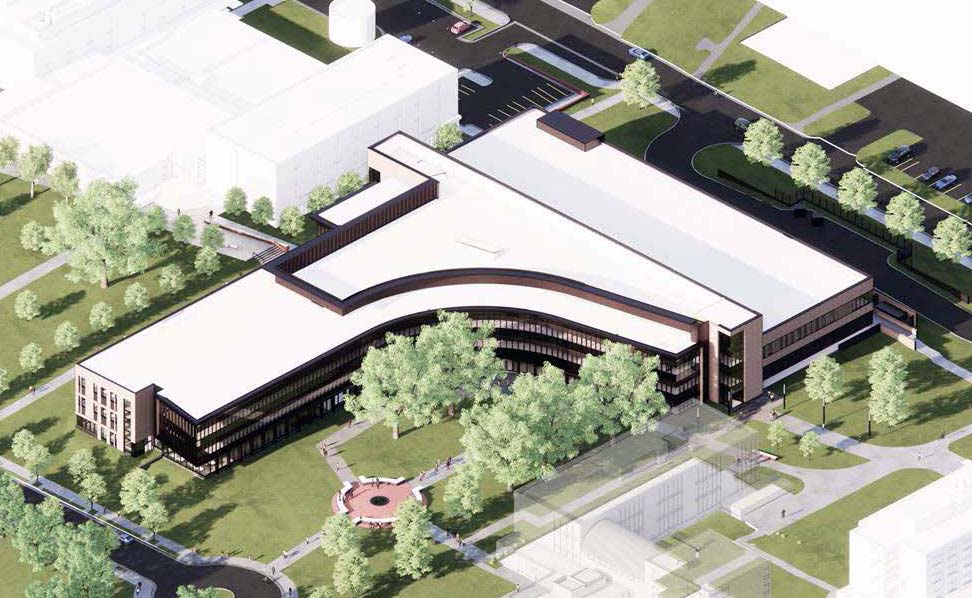

About this Project

ACI was awarded the mechanical, plumbing and fire protection scope for VSUs new 172K SF Academic building.

The project is designed to be a hub of intellectual activity on the campus, boasting three stories, 40+ high tech classrooms, 110+ faculty offices and other academic resources. The new building will be state-of-the-art and include a swimming pool, gymnasium, theatre, and exhibition gallery.

– 2 Chillers

– 6 RTUs

– 223 Term Units/Tracking Boxes/FCUs

– 6 Split Systems

– 12 Fans

– 210,000 lbs of Duct Fabrication

– 7 Water Heaters

– 160 Fixtures

UVA Olympic Facility

101, 000 Sq Ft Sports Complex

About this Project

ACI is the HVAC and Plumbing Design Assist partner for the new 101,000 square feet UVA Olympic Sports Complex. The design will include new Locker Rooms, Coaches and Staff Offices, Strength and Conditioning, Sports Medicine, Sports Nutrition, Recovery Room, Sports Science, and Technology. The Complex will be centrally located in the athletics precinct and feature Performance Training, Strength and Conditioning, Tutoring, Academic Support Spaces, and Hall of Champions.

Preconstruction is underway and ACI site work begins October of 2023, with final competition targeted for June 2025.

– Mechanical and plumbing systems

– 1 RTU

– 1 DOAU

– 190 TERM UNITS/TRACKING BOXES/FCUs

– 1 HEAT EXCHANGERS

– 1 WATER TREATMENT

– 140,000 LBS OF DUCT FABRICATION

– 317 FIXTURES

– 50,000 LF of combined plumbing and piping

Polykon Manufacturing

Aqua US Piping Upgrades

About this Project

When Polykon recognized the need for process improvement they selected Atlantic Constructors’ Industrial group to perform the mechanical scopes of work associated with the new process integration.

We completed the process improvement related process piping, utility piping, miscellaneous metals and rigging/equipment setting on this new state of the art pharmaceutical production facility on the Henrico County manufacturing campus.

– Process Piping Improvements

– Integration of new equipment into existing systems

– $500K

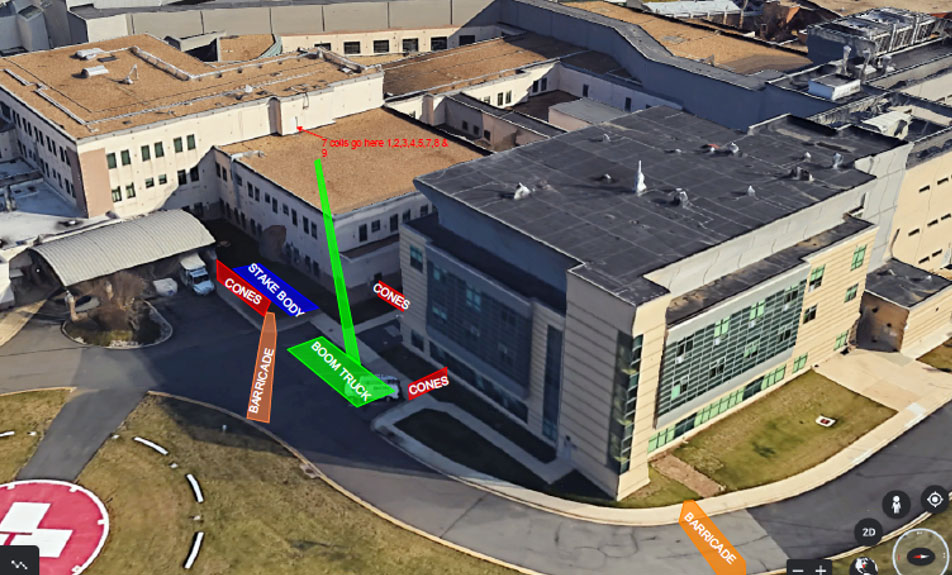

INOVA Loudoun Hospital

AHU Moisture Carry-over Project

About this Project

There are eight central station air handling units serving Inova Loudoun Hospital including all the patient care areas and the OR‘s. They have been having trouble with moisture carryover where excess moisture on the coils is driven downstream in the ductwork. To date, ACI has replaced four of the eight coils, all during off hours as to keep disruptions to a minimum.

ACI provided Design Assistance to help find a good approach for replacing the coils in the existing air handing units, while minimizing impacts to the end users. We laser scanned the inside and outside of every air handler so we could custom order coils to fit the dimensions of the existing air handling units. We also created a three-dimensional BIM model of the existing conditions outside of the air handler and then created piping spools, based upon the BIM model. The spools were prefabricated, palletized and shipped to the job site along with the coils. We built a temporary landing pad on the roof and were able to crane up and pre-stage all the prefabricated assemblies and coils. This approach allowed us to essentially take a unit down during off hours, and in a six-hour window, pull out the old coil, put the new coil in, pipe it back out, replace the control valve and reinsulate.

Four of the units were completed in the spring shoulder season. Another area, served by AHU-1, is currently under construction so we are able to complete it this week. The last three will be completed in the fall shoulder season.

Confidential Project

Research Facility

About this Project

DPR chose ACI as a their M&P partner for a brand new research facility in SW Virginia. This project had a very time sensitive schedule which led to several components of the job being pre-fabricated, including 100 Phoenix valves and seven process water skids. The project is expected to finish on time in February of 2024.

ACI performed the M7P scope of work on this $12M research facility (location undisclosed).

Equipment included:

– 3 Air Cooled Chillers

– 8 Air Handling Units

– 3 Strobic Fans

– 100 Phoenix Valves

– 7 Process Water Skids

# # #

Atlantic Constructors, Inc. is a full service industrial and commercial contractor headquartered in Richmond, VA (Chesterfield County) with satellite offices in Newport News, Roanoke, and Hampton Roads, VA. Our highly skilled team of over 700 employees serves customers throughout the mid-Atlantic region. For more information, visit www.acibuilds.com.